Deeside Power Station

Shortlisted for Project of the Year at the Construction News Specialists Awards 2024

Complete solution delivered on-site

Project completed with zero accidents, zero environmental incidents and zero trip events

Hughes and Salvidge were appointed to deconstruct part of the power station’s existing building, ensuring that the part that was being retained remained unaffected by the works.

The Client

Triton Power is the client and the work we undertook was at Deeside Power Station in North Wales.

Triton Power is a private, independent power generating company with a capacity of 1.35GW. They provide power to the UK wholesale electricity market through their UK power stations, playing an important role in security of supply when renewable generation does not deliver. Their combined output is sufficient to provide electricity for up to half a million homes in the UK. They pride themselves on safe, reliable and efficient operations, meeting obligations safely and in an environmentally-responsible manner.

Deeside Power Station is the site of an original 500MW gas-fired power station, ceasing generation in 2018. In a world-first conversion, both GT13E2 Gas Turbines were converted to run as synchronous compensators and are now providing zero MW, zero-emission stability services including inertia, reactive power and SCL for the National Grid. Deeside represents the epitome of reuse and recycle, and has utilised many of the plant items that were from its original design.

The Requirement

The project requirement was for part of the power station’s existing building to be deconstructed, ensuring that the part that was being retained remained unaffected by the works. The part being taken down was the HRSG - or Heat Recovery Steam Generator - which was constructed of a steel frame with external cladding.

Inside the HRSG were two gas-fired boilers with a 65m chimney for each, both of which were supported by a large heavy gauge steel A-frame. The structure also housed the top hung LP, MP and HP vessels required for each of the boilers. These all needed dismantling and removing without causing damage to the adjoining building. Some of the roofing needed to be removed to enable the separation and deconstruction to take place.

Project Delivery

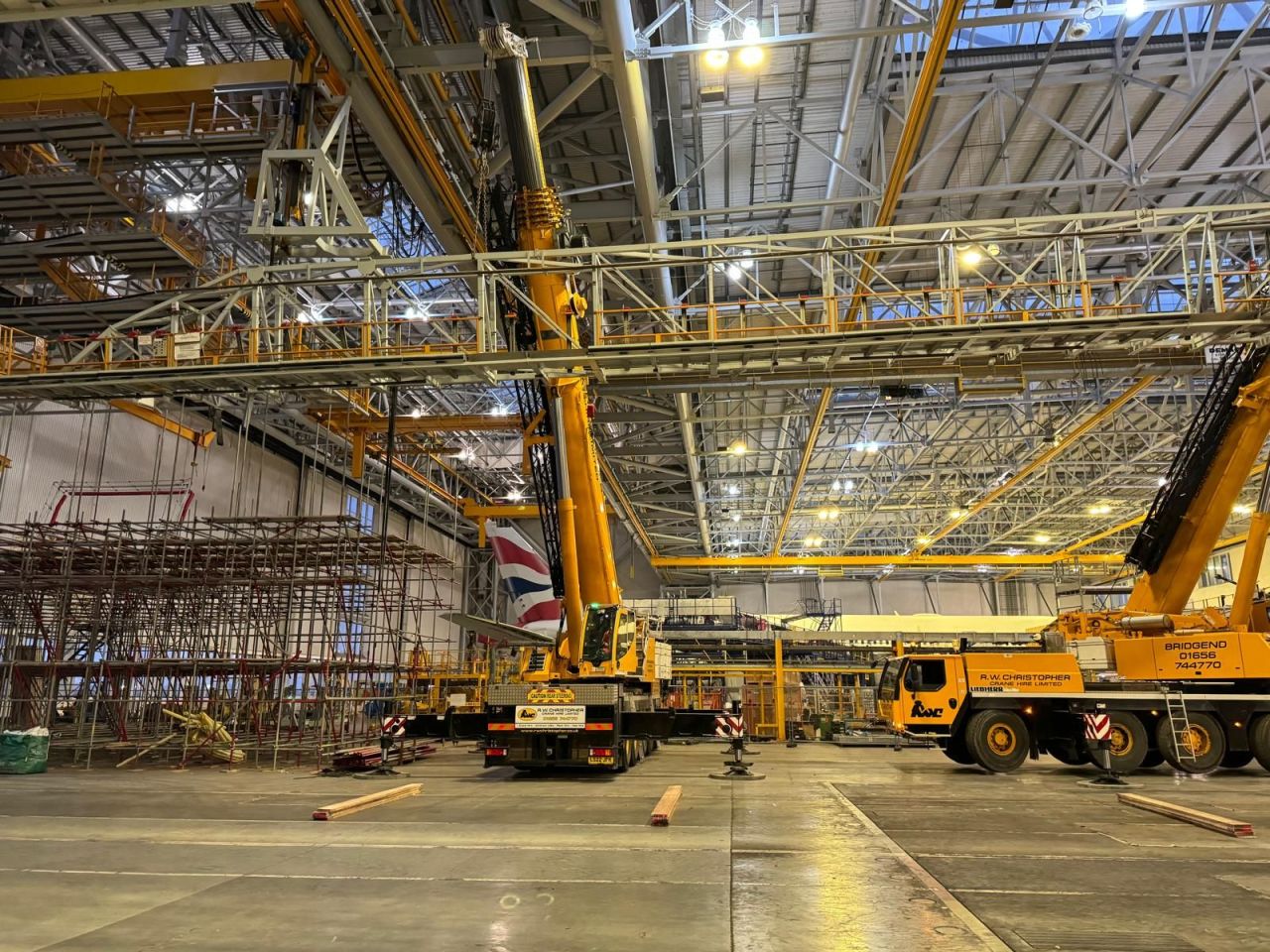

This project entailed a meticulous separation process, whereby our skilled team dismantled various elements of the structure with care to create a divide between the two parts of the building, before carefully deconstructing the two boilers, their chimneys and the frames supporting them.

The entire process was undertaken with consideration and rigour to ensure that all elements were safely dismantled and removed to preserve the remaining building, and ensure a smooth and safe process throughout.

The project was highly complex and high risk due to the heavy gauge steel structure of the building, so it involved meticulous planning and coordination by our on and off-site teams to achieve the successful dismantling of this 5,000t building.

Some key achievements during the project include:

-

Before commencing the project, our in-house CAD team produced a 3D model of the building which enabled us to design and plan the deconstruction and assist in the development of the lift plans.

-

Over 5,000t of steel was removed from this project of which approximately 2,000t was dismantled and lifted down by crane and operatives top burning.

-

All the plastic packing utilised during the project - 274 tonnes - was transferred for recycling at a specialist facility where it was shredded ready for reprocessing.

- We achieved successful completion of this project with zero accidents, zero environmental incidents and zero trip events, and our commitment to Safety, Health, Environment and Quality was showcased throughout the project. The complete solution that we provide - Demolish, Crush, Recycle - enabled this success.

The Outcome

The project, which commenced in early 2022 and finished in February 2023, was completed on time and on budget. The Project has been shortlisted for Project of the Year by a Specialist Contractor (subcontract up to £2m) at the prestigious Construction News Specialists Awards 2024. The results will be announced at the awards ceremony on 5 September.

A representative from Triton Power said: “The HRSG & Cooling Tower Demolition Project has been successfully completed at Triton Power, Deeside. This has been a challenging and very technical “dismantling" rather than a demolition, which was completed to world-class standards with zero accidents, zero environmental incidents and zero trip events. Thanks to everyone involved for your professionalism and diligence throughout the project.”

Explore some of the other projects we’ve undertaken as well as the services we provide…